FDA Foreign Facility Inspections: What Overseas Manufacturers Must Know in 2025

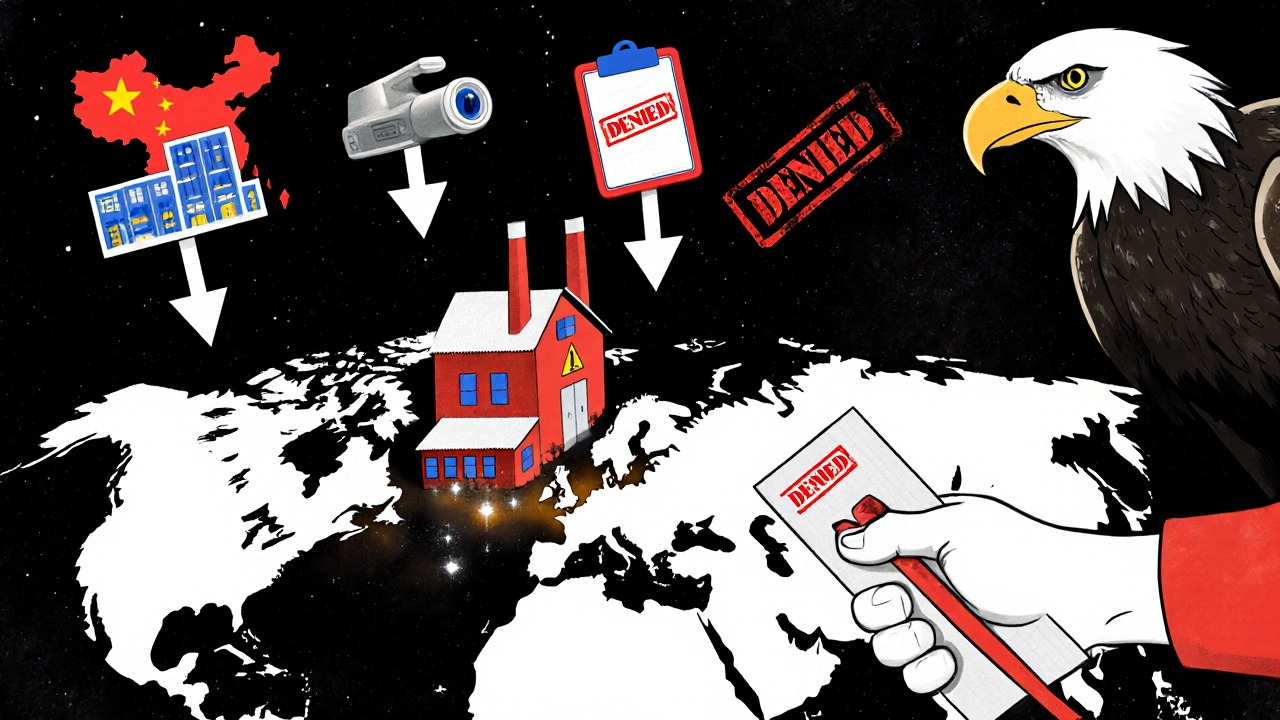

The U.S. Food and Drug Administration doesn’t just check factories in Ohio or California. Every day, it sends inspectors to food and drug plants in India, China, Mexico, Italy, and beyond. If your product ends up on a shelf in the U.S., it likely came from one of these foreign facilities-and the FDA is watching closer than ever.

Why Foreign Inspections Matter Now More Than Ever

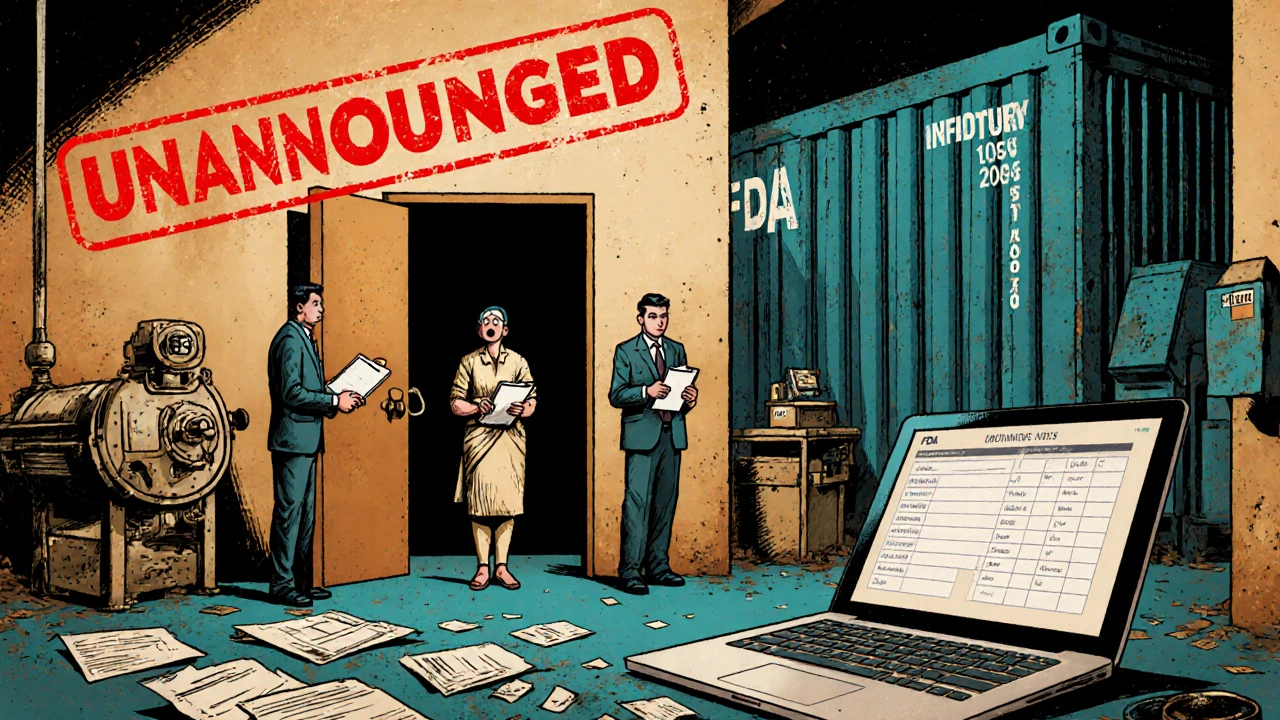

About 15% of the food Americans eat comes from overseas. That’s more than $180 billion worth of products every year. Fresh produce, spices, seafood, supplements, and even baby formula often cross borders before hitting grocery stores. But here’s the problem: if a factory abroad cuts corners, the contamination doesn’t stop at the border. Outbreaks of salmonella, listeria, and undeclared allergens have all traced back to foreign facilities that didn’t follow U.S. standards. The FDA Food Safety Modernization Act (FSMA), passed in 2011, changed everything. Instead of waiting for problems to happen, the FDA now has to prevent them. That means checking facilities before their products even get on a ship. But for years, there was a double standard. While U.S. plants got surprise visits, foreign ones got weeks of notice. They cleaned up, hired translators, hid issues-and inspections became more like guided tours than real checks. That changed in May 2024. The FDA announced it would start doing unannounced inspections at foreign facilities-just like it does at home. No more warning calls. No more time to fix things before the inspector walks in. If you’re exporting to the U.S., you must be ready every single day.How the FDA Picks Which Factories to Inspect

The FDA doesn’t have enough inspectors to visit all 300,000 registered foreign food facilities. So they don’t try. Instead, they use a risk-based system to pick targets. Three things decide if your plant gets flagged:- What you make - High-risk foods like raw sprouts, shellfish, or infant formula get top priority. Low-risk items like canned goods or baked snacks are lower on the list.

- How you make it - Complex processes with multiple steps, raw ingredients, or temperature-sensitive handling raise red flags. Simple packaging or bottling? Less concern.

- Your history - If your products got turned away at U.S. ports before, you’re now on the FDA’s watchlist. Refusals pile up fast.

What Happens During an Unannounced Inspection

Imagine waking up to a knock on your factory door. No call. No email. Just two FDA inspectors in suits, asking to see your records and your production line. They can inspect any part of your facility. That means:- Walking through your mixing rooms, even if you’re in the middle of a batch.

- Reviewing your training logs, sanitation schedules, and equipment maintenance records.

- Taking photos of your equipment, storage areas, and even your trash bins.

- Interviewing your staff-no translators provided by you.

- Delay the inspection

- Refuse to let them see a room

- Redact records

- Turn off cameras during inspection

- Block them from taking photos

What Foreign Facilities Are Doing to Prepare

Companies that survived the transition to unannounced inspections didn’t just panic-they adapted. One large supplement manufacturer in Bangalore started doing weekly internal mock inspections. They trained staff to treat every day like inspection day. They hired two full-time bilingual quality assurance officers. They moved all records to a cloud-based system that’s accessible 24/7-even from outside the country. Another seafood processor in Vietnam installed digital logs that automatically timestamp every cleaning cycle, temperature reading, and employee shift. No paper. No gaps. No excuses. The common thread? Constant readiness. No more “inspection week.” No more last-minute cleaning. You don’t prepare for the inspection-you live it.What Happens If You Fail

A failed inspection doesn’t mean immediate shutdown. But it does mean trouble. The FDA issues a Form 483 listing observations. This isn’t a fine-it’s a warning. If you fix the issues quickly, you might get another chance. But if you ignore it, or if the same problems show up again, the FDA can refuse entry of your products. That’s called a “Detention Without Physical Examination.” Your shipment sits at the port. No testing. No appeal. Just stuck. If you keep getting refused, the FDA can place you on an Import Alert. That means every future shipment gets automatically held. You have to prove you’ve fixed everything-sometimes with third-party audits-and wait weeks or months to get back on track. Some companies have lost 60% of their U.S. sales overnight after being placed on an Import Alert. That’s not just a setback. It’s a business killer.

Who’s Getting Left Behind

Big companies with global teams and compliance departments are adapting fast. But smaller operations? They’re struggling. A family-run spice mill in Thailand told a trade association they couldn’t afford a full-time quality manager. They used to get two weeks’ notice. Now they’re scared to answer the phone. They don’t know how to respond to an FDA inspector who walks in without warning. Language barriers are real. One inspector asked for “the last three months of calibration records” and the plant manager handed over a handwritten notebook from 2021. The inspector didn’t speak Thai. The translator wasn’t there. The shipment got detained. The FDA doesn’t make exceptions. They don’t care if you’re small. If you export to the U.S., you play by U.S. rules.What’s Next for FDA Oversight

The FDA isn’t stopping here. They’re testing AI tools to predict which facilities are most likely to fail based on past data, supplier history, and even weather patterns (yes, humidity affects mold growth in spices). They’re starting to use third-party auditors-approved and paid by the FDA-to do preliminary checks. These aren’t replacements, but they help prioritize who gets a full FDA visit. They’re also pushing for digital submission of records. Soon, you may not be able to hand over paper logs. Everything will need to be uploaded in real time. The goal? To make the U.S. the strictest, most reliable food safety system in the world. And if you want to sell here, you’ll need to meet that standard.Bottom Line: Are You Ready?

If you’re a foreign manufacturer exporting to the U.S., here’s your checklist:- Are your records digital, complete, and accessible 24/7?

- Do you have at least one bilingual staff member trained to handle FDA questions?

- Have you conducted at least five unannounced internal audits this year?

- Do you know what a Form 483 looks like-and how to respond to it?

- Have you trained your team to never delay, deny, or limit an inspection?

Are unannounced FDA inspections mandatory for all foreign facilities?

Yes. Since May 2024, the FDA conducts unannounced inspections at all foreign facilities exporting food, drugs, or medical devices to the U.S. This applies regardless of size, location, or past compliance history. Advance notice is no longer provided, except in extremely rare cases involving diplomatic or security concerns.

What happens if a foreign facility refuses an FDA inspection?

Refusing an inspection triggers an automatic refusal of entry for all products from that facility under Section 306 of FSMA. The FDA can also place the facility on an Import Alert, block future shipments, and refer the case to the U.S. Department of Justice for criminal prosecution. Obstruction of an FDA inspection is a federal crime.

Can a foreign facility hire its own translator during an FDA inspection?

No. The FDA does not allow regulated facilities to provide translators, lodging, or transportation. Inspectors use their own interpreters or rely on their own language skills. If a facility provides a translator, the inspection may be halted or deemed invalid. This policy ensures independence and prevents influence.

How often does the FDA inspect foreign facilities?

The FDA is required by FSMA to inspect high-risk foreign facilities at least once every three years. However, due to limited resources, many facilities are inspected less frequently. Risk-based prioritization means high-risk or non-compliant facilities may be inspected multiple times a year, while low-risk facilities may go years between visits.

Do FDA inspectors have the right to take photos during inspections?

Yes. FDA inspectors are legally authorized to take photographs, videos, and samples during inspections without prior permission. Facilities cannot block, cover, or interfere with photography. Refusing to allow photography can be considered obstruction and lead to enforcement action.

Can the FDA shut down a foreign facility?

The FDA cannot directly shut down a foreign facility. However, it can refuse entry of all products from that facility, place it on an Import Alert, and pursue criminal charges. In practice, being banned from the U.S. market often forces a facility to close or sell to a compliant buyer.

10 Comments

anant ram

November 29 2025Wow, this is huge for us small supplement makers in Bangalore. We’ve been doing mock inspections every week since last year-no more ‘inspection week’ nonsense. Every day is inspection day now. We’ve got bilingual QA staff, cloud logs, and even trained the cleaning crew to treat the floor like it’s being photographed. The FDA doesn’t play. And honestly? We’re better off for it.

Chuckie Parker

November 30 2025Finally. The U.S. is waking up. For years, foreign factories got a free pass while American plants got slammed with surprise checks. Now they’re held to the same standard. No more ‘we didn’t know’ excuses. If you want to sell here, you play by our rules. Period.

George Hook

December 1 2025It's worth noting that the shift toward unannounced inspections isn't just about enforcement-it's about building trust. Consumers in the U.S. are increasingly aware of where their food comes from, and they expect transparency. When a facility consistently meets standards without warning, it signals integrity. That’s the real win here: not punishment, but cultural change in global manufacturing.

jaya sreeraagam

December 1 2025My cousin runs a spice mill in Kerala and he was terrified at first-he thought the FDA would come in and shut him down for a typo in his logbook. But after we helped him digitize everything and train his team to speak basic English for inspections, he’s now got a 100% clearance rate. It’s not about perfection-it’s about consistency. And yeah, I spelled ‘Kerala’ right this time. 😅

Katrina Sofiya

December 2 2025This is an incredibly important update for global food safety. The FDA’s commitment to equity in inspection standards is both principled and practical. By removing the ability to prepare in advance, we ensure that safety protocols are embedded in daily operations-not just performed for auditors. This model should be adopted worldwide.

kaushik dutta

December 4 2025Let’s be real-the FDA’s new policy is a wake-up call for the entire global supply chain. Jargon-heavy compliance docs don’t save you. Translation apps won’t cut it. If your facility still relies on paper logs and ‘we’ll fix it tomorrow’ culture, you’re not just at risk-you’re already failing. The U.S. market isn’t a charity. It’s a fortress. And the gates are locked.

Nicola Mari

December 6 2025It’s pathetic how many foreign manufacturers still think they can get away with laziness. Handwritten notebooks? No translators? You’re not a small business-you’re a public health liability. The FDA should be publicly naming and shaming these places, not just detaining shipments. Some people need their names on a wall of shame.

Sam txf

December 7 2025These inspectors are basically superheroes-showing up unannounced, no fancy hotels, no free meals, just doing their damn job while some factory owner tries to hide stuff in a closet. Meanwhile, we got people in the U.S. complaining about FDA delays. Bullshit. If you’re not ready, you shouldn’t be selling here. Period. End of story.

Michael Segbawu

December 9 2025So like the FDA just walks in and takes pics of your trash bins like its a reality show? Bro that’s wild. I mean I get it but why not just let us send the records online? Why make people panic? Also my cousin’s factory got held up for 3 months because someone wrote ‘2021’ instead of ‘2022’ on a log. That’s not safety thats just bureaucracy gone rogue.

Aarti Ray

December 9 2025My aunt’s family business in Chennai used to get 2 weeks notice. Now they’re scared to answer the phone. But they finally hired a young grad who knows English and tech-now everything’s in the cloud. No more panic. Just calm, daily checks. It’s not perfect, but it’s working. The FDA isn’t the enemy. Being unprepared is.